Celestain designs and manufactures Automated Process Management System (APMS). APMS is designed to: (a) manage critical processes that require continuous monitoring and precise controlling (b) monitor and study the natural phenomena and (c) study the process response to its environment modulations. The areas of APMS application include: fundamental research, structural analysis, wind tunnel testing, reliability study, manufacturing treatments, industrial process automation & control, study of natural phenomena and study of reactive response. APMS is highly programmable by the user for various applications, sensors and process parameters. APMS is designed for safety & mission critical applications .

APMS acquires real-time data from related sources simultaneously. The system is scalable to acquire large number of channels carrying various types of signals and data. The system supports analogue, digital, RF and optical signals from a variety of sensors and data busses.

AMPS data acquisition is user programmable. The signals are automatically compensated for variations in the environment.

APMS manages a process by controlling the excitation and environment parameters that influence the process. The process controls are computed from the planned values and actual status. Process control applications are automated with programmable frequency, precision and accuracy.

In applications where the process environment cannot be controlled (e.g. study of natural phenomena), the environment and the process parameters of interest are monitored and acquired.

In Controlled Process Monitoring applications, APMS controls the environment and acquires the data of the process being studied.

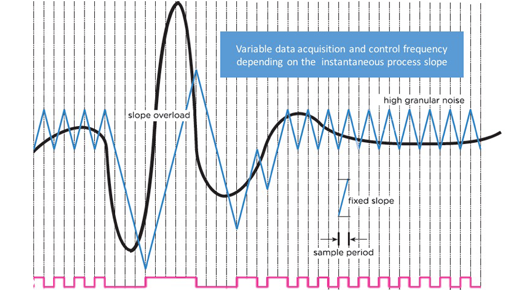

APMS implements adaptive algorithms to dynamically adjust the data acquisition and control rate depending on the process trend and instantaneous slope.

This feature enhances the resolution of data in the areas of interest. This algorithm is programmable by the user.

APMS is capable of managing multiple and heterogeneous processes environments simultaneously. Customers achieve higher ROI in a single investment in a single versatile system.

APMS process management parameters and environment are user configurable. APMS applications are also user configurable for managing different kinds of processes. ROI is manifold for organizations having different kinds of process management needs.

APMS is a configurable software system. It adapts to a variety of process control and monitoring hardware and instrumentation. This feature enables full reuse of existing process management hardware and support of multi-vendor process management components.

APMS design is based on Abstracted SoA Architecture. Existing process management systems can be integrated to have a single point common control. Organizations can improve their operations efficiency and cost savings.

APMS is highly scalable by the addition of IO channels in the Data Acquisition & Control. Besides the user configurable scalability, the solution is available in various form factors to fit the small, medium and large scale requirements.

APMS is designed with full hot-standby redundancy. From the sensors to backend processing, all the functions are backed up by redundancy without any data loss.

Celestain undertakes turnkey projects to develop, install and commission APMS solutions for all the sizes and types of the industry.